If you follow the Logistics Bureau blog, you might recall that we have, once or twice, made passing reference to the concept of the circular supply chain, primarily in our articles focused on developing trends in the supply chain and logistics sector.

In the summer of 2020, I had the opportunity to interview bona fide circular supply chain authority, Deborah Dull, to get a comprehensive expert overview of the concept and what it means for enterprises, organisations, and supply chain practitioners.

Circular supply chains are Deborah’s passion. Aside from founding a professional community called the Circular Supply Chain Network, she has also penned and published an entire book on the subject.

For a bite-sized but thorough glimpse at the topic, though, the following transcript of our interview, I’m sure you will agree, makes for a valuable few minutes of insight into the circular economy and the corresponding circularity of the future supply chain.

An Expert’s Take on the Circular Supply Chain

Rob: So, Deborah! Thank you very much for joining us today. You have a fascinating background with the Gates Foundation, in case our audience wasn’t aware of that, but you’re also a true expert in the circular supply chain, so let’s get right into that topic. The circular supply chain—what’s that all about?

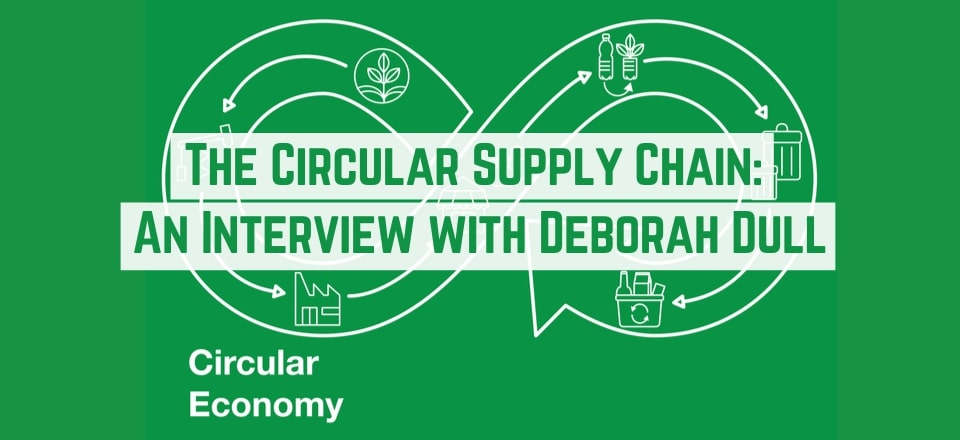

Deborah: So, the supply chains that we have today support our current global economy, of course, and that economy works in a line. We take something out of the planet or maybe from a forest. We make something with it very efficiently. We use that item, and then typically, we throw it away.

And there’s a new realisation over the last ten years or so that we will not have infinite amounts of resources—so we’ll have to find another way to have this global economy work. So you can put circular supply chains into two categories:

1) Those supply chains that support circular business models that are participating in this new type of global economy

Or…

2) Supply chain operators who are going circular themselves, as a catalyzing factor to support any business model.

Examples of the Circular Supply Chain in Action

Rob: Okay, so let’s dig a little bit deeper. Can you give us some examples of the two categories and what they look like?

Deborah: Okay, we’re seeing an interest in two categories of materials and resources. One of those categories is called renewable materials and comprises anything that would go back into the planet. It could be heat, water, food scraps, and composting—anything like that which goes back into the earth or its atmosphere.

One exciting thing that I hadn’t thought of before entering the space is heat runoff. Today so much of the heat that industry generates in various operations is just lost. It’s going into the atmosphere. But now, we are starting to see regenerative processes that harness that heat and use it in another operation or for some practical purpose.

For example, I’m sitting in Seattle, not far from the biospheres that the team at Amazon has built, and those are heated with server heat runoff. So that’s the one category comprising renewable, regenerative type of material.

Then we have what’s called technical materials. Those are like plastics, metals, and other items that would not go back into the planet—and this is where it gets exciting.

Recycling is a Last Resort

We start seeing material science innovations and exploring ways to use materials forever. So the idea is, for instance, that this plastic we have running around the planet should continue to be used rather than trying to make new plastic.

The challenge, of course, is that every time we process or recycle any material, it loses some integrity. So a principle of the circular economy is to find other ways to be stewards of this material.

Recycling is a very last resort in a circular business model. You want to leave the material as it is for as long as possible. So it’s about things like rethinking product design. For supply chains, that could mean more modular design or refurbishment and remanufacture along the same lines as manufacturing a new product.

The name of the game really will be switching to refurbishment, remanufacture, and reuse. In the coming five to ten years, the expectation is that most businesses would shift to remanufacture rather than starting from scratch.

Money and Risk: The Carrot and Stick of Circular Economics

Rob: So, how do we encourage companies to participate more in this circular economy? Perhaps a large part of this is recycling? What are the incentives for enterprises to do that? Do we need government initiatives? Are there specific industries that need to be pushed towards it?

Deborah: Money is the most effective carrot. It’s the incentive for businesses anchoring in the three circular principles. Those principles are:

A) Design out waste, which we know how to do in the supply chain. That could look like product-as-a-service instead of selling products.

B) Keeping materials in play—for example, refurbished cell phones.

C) Regenerating natural systems.

Those companies that anchor into these principles properly make big money doing it, so that’s the most significant incentive. If you think you’re engaged in a circular business model, but your business is not making money, you need to take another look because there may be something you’re missing.

I will say this is one of the few spaces I’ve ever seen where government policy is out ahead of the business community. There’s lots of money to be had here. Many incentives are already in place, particularly in Europe, although Australia and several Asian countries are also well incentivising businesses to take a look at this.

The other significant factor to consider is disruption and risk to your supply chain. We’re starting to see some risks around raw materials, particularly copper. Anyone in sourcing who buys large quantities of copper will already know what I mean. We’re running out.

We have less than ten years left of gold. What that means, of course, is that there will be a dearth of gold quantities viable for mining. We use gold in everything—in many different electronics, for example. So there’s a considerable risk to the ability of supply chains to function.

At the beginning of the supply chain, we will have a substantial risk to address. But then also, as we are seeing so much more of today, the longer a supply chain is, the more chances there are for disruption in its functioning.

The premise of the circular economy is to explore whether you can get resources locally, transform them locally and use them locally. Of course, you can’t always do that, so we’ll continue to see global trade in some cases. But for little widgets, for instance, you shouldn’t need to be ordering those online from some central warehouse several hundred kilometers away. Perhaps they can be 3d printed, right there in your locale.

So there’s a whole shift coming, which I think could be pretty interesting. Indeed, I encourage people to visit the web pages of the Ellen MacArthur Foundation. They’re a prominent thought leader in the space. They’ve highlighted many nice case studies covering the last couple of years.

Circular Economy: Industry by Industry

Automotive is probably the furthest ahead. If 15 years ago, we were to say you could get something like a BMW-certified, used car, people would have rolled their eyes and thought there’s no way that BMW would ever let that happen. But in fact, such a thing has become a reality today.

So refurbishing used cars is along that vein, and Renault is undertaking a classic example of that in France, and they’ve made tremendous amounts of money from these new types of revenue streams. The cars are not junked. They are recaptured, refurbished, and reused, so the parts concerned are already there. There’s no starting from scratch to make new or spare parts. From refurbishing like this, they’re able to make considerable sums of money.

Fashion, too, is in focus right now. We have this love affair with fast fashion as consumers. Some breakout brands are now taking approaches such as cut-to-order—so you might input your actual measurements onto a website, and they won’t even cut the fabric until they’ve received your order. Then they do the cutting with a laser, which reduces waste.

We’re seeing print-to-order, which means keeping the silhouette of an item but moving color with the season since colors are a bit fickle, as are consumers.

The other area we’re seeing a keen focus on is single-use plastics and single-use coffee cups, for example, and there are many leaders in this space. Starbucks, for instance, is running an ongoing cup challenge to figure out what they’re going to do. So they’ve done substantial research and invested in concepts such as a reusable coffee cup network, which would allow you to get your coffee in a robust to-go cup for reuse and return it at any number of other locations. The cups would all be continually captured as part of a network.

Finally, food is worth mentioning. A third of the food in the US system today is wasted. Meanwhile, we have this terrible problem globally in that some people are going hungry—and we are discarding food.

Aside from that, food production consumes water, energy, and other resources, while food scraps that we throw away—which could instead be composted—contribute almost 7% of the world’s greenhouse gases.

Seven percent! That’s more than three times the contribution of air travel. We hear a lot about how destructive air travel is environmentally, and it is, but on aggregate, something as nondescript as composting can drive huge improvements in sustainability.

See and Hear More About the Circular Economy and Supply Chain

For me, and I’m sure you’ll agree, Deborah’s insights were remarkable, and shed considerable light on the circular economy and the supply chain implications.

To learn more from Deborah, you can visit her website, called deborahdull.com. And while you’re at it, why not check out The Supply Chain Revolution podcast? It features some fascinating episodes on the circular economy, in which Deborah and her co-host explore the concept in several different ways.

If you haven’t had a chance to watch the video from which this transcript is extracted, feel free to stop by at the Supply Chain Secrets YouTube channel and pay it some attention.

You’ll find a ton of other interviews with notable supply chain experts there, along with hints and tips from me and the Logistics Bureau team, to help you boost your company’s supply chain performance.

Editor’s Note: The content of this post was originally published on Logistics Bureau’s website dated February 1, 2022, under the title “Talking Circular Supply Chains with Deborah Dull“.